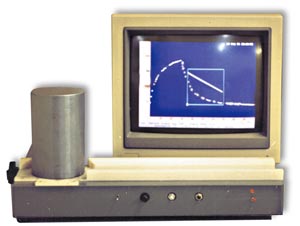

| MICROWAVE

RELAXOMETER |

| The

device is assigned for express non-destructive contact less local

measurement of non-equilibrium charge carrier effective lifetime

in silicon substrates, epi-wafers and solar cells at different

stages of manufacturing cycle. It can be used for incoming and out coming

inspection of silicon ingots and wafers, tuning and

periodic inspection of semiconductor IC technology quality.

Lifetime determination is based on measuring photoconductivity

decay after pulse-light photo-exciting using reflected microwave

as a probe. |

|

MAIN

TECHNICAL PARAMETERS

|

| Silicon

resistivity range, Ohm.cm |

1÷100

|

| Measurement

locality, mm |

0.5÷2.0

|

| Measurement

duration, min. |

| |

in

spot |

0.5

|

| 150

mm wafer scanning |

30

|

|

|

| Microwave

Relaxometer is produced in several design versions: |

| |

| MWR-E

Series Engineering version: |

|

| measurement

of true non-equilibrium charge carrier bulk lifetime, surface

recombination velocity, electro-active defect density;

| manual

specimen loading and moving, manual signal level adjustment;

| recommended

for scientific laboratories, quality assurance laboratories at

manufacturing fabs and also for ingot inspection. |

| |

|

| |

| MWR-SI

Series Semi-Industrial version: |

|

attestation

of incoming materials, equipment and technology quality;

|

manual

specimen loading, manual signal level adjustment, automatic

specimen movement following pre-set inspection pattern

(including full wafer topograph);

|

recommended

for incoming and diffused wafer inspection plants.

|

| |

|

|

| MWR-I

Series Industrial version: |

| routine

automated inspection of silicon wafers;

| automatic

cassette-to-cassette loading, automatic signal level

adjustment, automatic wafer sorting;

| recommended

for automated semiconductor IC and solar cell manufacturing

lines; |

| |

|

| |

| Lifetime

measurement process is automated on the basis of IBM PC. |