| MAGNETRON

SPUTTERING MACHINE UNITS |

| |

|

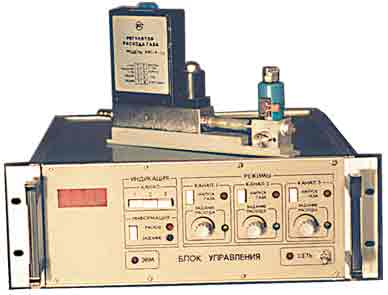

Three-Channel

Gas Flow Control System

|

| The

system includes power&control unit with the socket for PC

connection, three electronic mass flow controllers and three

electromagnetic stop valves. Each of three working gas flows is

maintained independently with the accuracy ± 1% of maximum flow

value. At customer's order the system is equipped by 0.9-90 l/hour

mass flow controllers. Each channel flow iis entered independently

with numerical task indication. |

|

| |

| Extended

Magnetrons |

| Extended

Magnetrons Magnetrons can be placed either inside or outside (on

flanges) vacuum chamber and provide uniform deposition area width

from 400 and up to 1500 mm. Other width value may be provided at

customer's order. Due to stable work at low pressure magnetrons

provide the possibility of ion treatment during deposition with

the purpose of layer modification, hardening etc. |

| |

|

|

| |

| Target

voltage (negative), V |

350

- 650

|

| Target

current, A |

1

- 40

|

| Operating

pressure, Pa |

0.07

- 0.2

|

| Layer

thickness uniformity, % |

±

5

|

| Maximum

power consumed, kVA |

40

|

| Target

thickness, mm |

10

|

| Target

use ratio, % |

35

- 40

|

| Coolant

conventional pass diameter, mm |

6

- 12

|

| Coolant

pressure, HPa |

3

- 4

|

|

| |

|

Deposition

area width, mm

|

Dimensions,

mm

|

Weight,

kg

|

|

400

|

600

x 137 x 70

|

9.0

|

|

600

|

780

x 137 x 70

|

12.0

|

|

800

|

1000

x 137 x 70

|

18.0

|

|

1300

|

1640

x 137 x 70

|

31.0

|

|

|

|

| Extended

Ion Beam Gun |

| Ion

beam guns are assigned for ion cleaning of substrates (including

metallic and glass ones) prior to depositing any layer as well as

for ion and ion-chemical etching of metals, semiconductors and

dielectrics. Ion beam guns can be placed either inside or outside

(on flanges) vacuum chamber and provide uniform ion-treatement

area width 160, 350, 450, 650 and 900 mm. Other width value (up to

more than 2000 mm) may be provided at customer's order. As ion

beam gun current depends by design only on gas flow devices can

operate in a pressure range from 0.01 and up to 0.4 Pa providing

the possibility of ion treatment directly in magnetron deposition

process and of ion assistance during thermal, ion-beam, arc

deposition and reactive magnetron sputtering. |

| |

|

|

| |

|

Discharge

voltage (positive), kV

|

1.5

- 4.0

|

|

Discharge

current, mА

|

300

- 2000

|

|

Gas

consumption, ccms/0.5 А

|

1

|

|

Specific

current per 1 cm of treatment area width, mA/cm

|

no

less than 15

|

|

Maximum

power consumed, kVA

|

4.0

- 6.0

|

|

| |

|

Ion-treatment

area width, mm

|

Dimensions,

mm

|

Weight,

kg

|

|

160

|

230

x74 x 45

|

3.0

|

|

350

|

400

x 74 x 45

|

5.0

|

|

450

|

534

x 74 x 45

|

7.0

|

|

650

|

696

x 74 x 50

|

12.0

|

|

900

|

1016

x 74 x 55

|

18.0

|

|

| |

| Compact

Ion Beam Gun with Cold Cathode |

| This

ion beam gun may be extremely beneficial for laboratory

purposes.It can work hundreds of hours without maintenance.As

discharge characteristics of the device are pracically gas type

independent it can be used with any working gas.Operating

parameters of the device are gas flow dependent and almost gas

pressure independent untill maximum working pressure is reached.

Ion beam gun can be placed either inside or outside (on flanges)

vacuum chamber. |

|

|

| Ion

beam diameter, mm |

20

|

| Maximum

discharge voltage (positive), kV |

4.0

|

| Maximum

discharge current for short time (no more than 10 min.)

switching, mA |

120

(+ 3.5 kV)

|

| Recommended

discharge current for long time switching, mA |

80

|

| Gas

(Argon) consumption at 80 mA discharge current, ccms |

0.15

|

| Recommended

working pressure, Pa |

no

more than 0.5

|

| Diameter,

mm |

60

|

| Length,

mm |

50

|

| Weight,

g |

200

|

|